Polymer:

Polymer is a complex, giant macromolecules made from repeating units which are derived from small molecules called as monomer.

Classification of polymers:

Classification of polymers is based on :

- Source of origin.

- Chemical structure.

- Mode of polymerization.

- Molecular forces.

- Types of monomers.

- Biodegradability.

Polymers are divided into three categories: a. Natural b. Synthetic c. Semisynthetic

a. Natural polymers: The polymers obtained from natural source are said to be natural polymers. They are further subdivided into two types.

• Plant polymers: These are obtained from plants. For example Natural rubber is manufactured from the latex obtained from bark of rubber trees.

• Animal polymers: These are derived from animal sources. For example, wool is obtained from hair of sheep.

b. Synthetic polymers:

These are man made polymers. These polymers are artificiallyprepared by polymeruzation of one monomer or copolymerization of two or more monomers. Nylon, terylene,neoprene are synthetic polymers. These are further divided into three subtypes, namely fibres, stnthetic rubber and plastic.

These are derived from natural polymers. These are also called regenerated fibres. Cellulose derivatives such as cellulose acetate rayon, cellullose nitrate, viscose rayon are few eaxamples of this categary.

Semisynthetic polymers are used in preparation of non- flammable photographic films, cinema films, varnishes, etc.

2. Classification of polymers on the basis of structure :

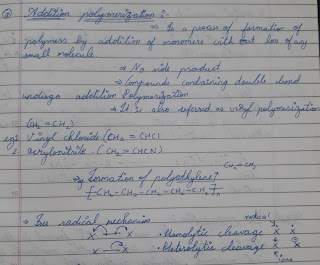

Step 1: Chain initiation: The chain reaction is initiated by free radic. An initiater such as benzoly peroxide, acetyl peroxide, tert-butyl peroxide., ect. can be used to produce free radical. For example acetyl peroxide generates methyl radical as shown below:

Step 2. Chain propogation: The new radical formed intitiation step reacts with another molecule of vinyl monomers, forming another still bigger sized radical, which in turn reacts with another monomer molecule. The repetition of this sequence takes place very rapidly. It is called chain propogation. This step is very rapid and leads to high molecular mass radical.

Step 3. Chain termination: Ultimately, at some stage , termination of the growing chain takes place. It may occur by several processes. One mode of termination is by combination of two growing chain radicals.

c.Thermoplastic polymers:

Plastucity is a property of being easily shaped or moulded. Thermoplastic polymers are capable of repeated siftening on heating and hardening on cooling. These polymers posses moderately strong intermolecular forces that are intermediate between elastomers and fibres. For example: polythene, polystyrene, etc.

d. Thermosetting polymers:Thermosetting polymers are rigid polymers. During their formation they have property of beinh shaped in heating; but they get hardened while hot. Ince hardened these become influsible; cannot be softened by heating and therefore cannot be remoulded. This characteristic is the result of extenssive cross linking by covalent bonds formed in the moulds during hardening process while hot. For example: bakelite, urea,etc.

5. Classification of polymers on the basis of type of different monomers:

Polymers are divided into two classes:

a. Homopolymers:

The polymers which have only one type of repeating unit are called homopolymers. Usually they are formed from single monomer. In some cases the repeating unit is formed condensation of two distinct monomers. For example: polythene, polypropene,etc.

b. Copolymers:

The polymers which have two or more types of repeating units are called copolymer. They are formed by polymerization of two or more different types of monomers in presence of each other. The different monomer unit are randomly sequenced in the copolymer. For example: Buma-S, Buna-N.

6. Classification of polymers on the basis of biodegradability:

Most of the synthetic polymers are not affected by microbes. These are called non- biodegradable polymers. These in the form of waste material which stays in the environment for very long time and pose pollution hazards. Most natural fibers in contrast are biodegradable. In attempt to tackle the environmental problems, scientists have developed biodegradable synthetic polymers.

Related topics:👇

●speech-on-courtesy-is-light-of-life

●https://247studentsrule.blogspot.alcohol-classification-properties-

●https://247studentsrule.blogspot.com/2020/09/crystal-defect.html

Comments

Post a Comment